Although not a new technology (developed in the late 1980), the 3d printing patents have recently expired, thus more and more personal printers became available from a plug and play option to a multitude of DYI designs. The majority of these printers use the Fused Deposition Modeling technology where a plastic filament is melted through an extrusion nozzle and deposited in layers with the control from a computer.

|

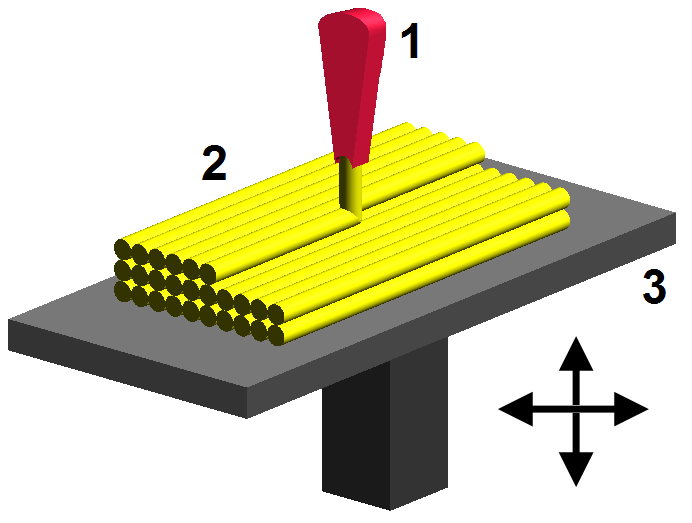

| Fused deposition modeling: 1 – nozzle ejecting molten plastic, 2 – deposited material (modeled part), 3 – controlled movable table. |

There are multiple designs options when it comes to 3d printers. The variations are generated by the need to move the extrusion nozzle in rapport with the print bed in X, Y, Z space. The conventional notation is:

- X axis is left to right;

- Y axis is forward to backward;

- Z axis is down to up

With this convention the variations can be identify as:

- The Gantry Style - the extruder moves in X and Y axes while the print bed moves in the Z axis. The object is build layer after layer

- The Moving Bed - the print bed moves on two axes (usually the Z and Y axis) and the extruder moves on X axis.

- The Delta Style - the print bed is fixed and the extruder moves in all three axes by the move of three support rods either linear or circular

So why I chose the delta design and why I chose Kossel mini?

I dismissed the moving bed from the beginning. I want to be able to print tall objects, so the image of having the object moving on a horizontal axis all the time was a problem. I looked for some affordable kits that use the gantry style and I could not find any.

I stubble upon a video of a delta robot printing, and all looked so natural. The light weight of the printing head (using the Bowden tube) allows for fast printing speeds.

The main disadvantage of the delta configuration is that the movement of the motors and the support rods does not translate in a direct movement on the X, Y or Z axis. So tweaking and adjusting is harder. On this note I think the amount of information available online and my patience will help me finish the assembly and calibration.

I will document my steps and challenges on this blog, so let's get started with the first post.

No comments:

Post a Comment